Support the forum

Navigation

-

- Men's Style

- Classic Menswear

- Streetwear and Denim

- Preorders, Group Made-to-order, trunk shows, and o

- Menswear Advice

- Former Affiliate Vendor Threads; a Locked Forum.

- Career and job listings in fashion, mens clothing,

-

- American Trench

- AMIDÉ HADELIN

- Archibald London

- The Armoury

- Arterton

- Besnard

- Canoe Club

- Capra Leather

- Carmina

- Cavour

- Crush Store

- De Bonne Facture

- Drinkwater's Cambridge

- Drop93

- eHABERDASHER

- Enzo Custom

- Epaulet

- Exquisite Trimmings

- Fils Unique

- Gentlemen's Footwear

- Giin

- Grant Stone

- House of Huntington

- IsuiT

- John Elliott

- Jonathan Abel

- Kent Wang

- Kirby Allison

- Larimars Clothing

- Lazy Sun

- LuxeSwap

- Luxire Custom Clothing

- Nicks Boots

- No Man Walks Alone

- Once a Day

- Passus shoes

- Proper Cloth

- SARTORIALE

- SEH Kelly

- Self Edge

- Shop the Finest

- Skoaktiebolaget

- Spier and MacKay

- Standard and Strange

- Bespoke Shoemaker Szuba

- Taylor Stitch

- TLB Mallorca

- UNI/FORM LA

- Vanda Fine Clothing

- Von Amper

- Wrong Weather

- Yeossal

- Zam Barrett

Install the app

More options

-

Hi, I am the owner and main administrator of Styleforum. If you find the forum useful and fun, please help support it by buying through the posted links on the forum. Our main, very popular sales thread, where the latest and best sales are listed, are posted HERE

Purchases made through some of our links earns a commission for the forum and allows us to do the work of maintaining and improving it. Finally, thanks for being a part of this community. We realize that there are many choices today on the internet, and we have all of you to thank for making Styleforum the foremost destination for discussions of menswear. -

This site contains affiliate links for which Styleforum may be compensated.

-

STYLE. COMMUNITY. GREAT CLOTHING.

Bored of counting likes on social networks? At Styleforum, you’ll find rousing discussions that go beyond strings of emojis.

Click Here to join Styleforum's thousands of style enthusiasts today!

Styleforum is supported in part by commission earning affiliate links sitewide. Please support us by using them. You may learn more here.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Shoemaking Techniques and Traditions--"...these foolish things..."

- Thread starter DWFII

- Start date

- Watchers 211

- Joined

- Jan 8, 2008

- Messages

- 10,132

- Reaction score

- 5,714

I'm not sure. I mostly see this damage in heel stacks and the heel area of insoles. I don't know anyone that uses chrome tannages for outsole or insole or heel stacks (although a chrome tanned ousole is available for ballroom dancers).

That said, I've never seen the initial stain from the reaction between moist chrome and iron. And maybe even more telling, undyed chrome will not take the iron black dye.

Meaning the oxidative reaction is not happening. And FWIW, oxidation in/on iron and rust are the exact same thing.

@DWFII

In your recent posts regarding nails / pegs and heel stacks you've made some emphasis on the detrimental effects of nails in veg tanned leather. I'm just wondering, would chrome tanned leather fare even worse (or ? better) in this regard?

Thanks in advance!

I'm not sure. I mostly see this damage in heel stacks and the heel area of insoles. I don't know anyone that uses chrome tannages for outsole or insole or heel stacks (although a chrome tanned ousole is available for ballroom dancers).

That said, I've never seen the initial stain from the reaction between moist chrome and iron. And maybe even more telling, undyed chrome will not take the iron black dye.

Meaning the oxidative reaction is not happening. And FWIW, oxidation in/on iron and rust are the exact same thing.

Last edited:

- Joined

- Nov 12, 2007

- Messages

- 1,949

- Reaction score

- 1,543

Well, my writings are certainly sincere.

I never said that your heel bases would come off.

I answered the question asked of me. And, yes I've seen them sheered off. Just sharing my experience.

Well, thank you for the kind words and vote of confidence.

That said, I've never had a heel base come off accidentally (no brag) and the men who I make boots for ride hard and put up wet. They work! In condition and at jobs that I suspect most of your dress shoe customers would blench at. Their boots see Xtreme daily and to a degree that what you're calling "extreme" might very well be considered high cotton.

Well, my writings are certainly sincere.

I never said that your heel bases would come off.

I answered the question asked of me. And, yes I've seen them sheered off. Just sharing my experience.

ThunderMarch

Distinguished Member

- Joined

- Oct 23, 2014

- Messages

- 1,734

- Reaction score

- 1,806

Thanks for the explanation. I understand your reference with regards to heel stacks and veg tan.

I should have been more clear, as I also had in mind the recent discussion of how the uppers and insoles (at the heel area) are attached, and how some makers would drive nails in this area....

But then again, you've also made your point on how non optimal this method is in itself.

Much learnt from all your sharing, as usual. Thanks !

I'm not sure. I mostly see this damage in heel stacks and the heel area of insoles. I don't know anyone that uses chrome tannages for outsole or insole or heel stacks (although a chrome tanned ousole is available for ballroom dancers).

That said, I've never seen the initial stain from the reaction between moist chrome and iron. And maybe even more telling, undyed chrome will not take the iron black dye.

Meaning the oxidative reaction is not happening. And FWIW, oxidation in/on iron and rust are the exact same thing.

Thanks for the explanation. I understand your reference with regards to heel stacks and veg tan.

I should have been more clear, as I also had in mind the recent discussion of how the uppers and insoles (at the heel area) are attached, and how some makers would drive nails in this area....

But then again, you've also made your point on how non optimal this method is in itself.

Much learnt from all your sharing, as usual. Thanks !

Last edited:

- Joined

- Nov 12, 2007

- Messages

- 1,949

- Reaction score

- 1,543

Maybe I got this wrong......From what you are implying, water/moisture purges through the lateral portion of the base rusting nails that are coated? If so, why wouldn't the layers of the stack swell, soften and de-laminate?

I'm sorry...case in point--you don't know what you're talking about.

It is not mildew. It is a reaction (the initial reaction in a cycle of oxidation) between the tannin and acids in the leather and the iron.

Here is an experiment that even a non-shoemaker can do:

Take a piece of your vaunted Rendenbach. Dip it in water and let it soak for about ten minutes. Lay it on a well aerated counter flesh side up. Now place an piece of iron on it--a hammer, a pliers or even an iron nail. Let the leather dry overnight. There will be a black stain on the leather in the shape of the iron object.

Not, not, not mildew.

Here's another experiment you home experts can do: All you need is a piece of naturally coloured vegetable tanned leather, a bunch of steel wool (or a quart of old bent discarded iron tacks) and some vinegar.

Place the tacks or steel wool in a plastic bucket and cover with vinegar. Let sit overnight. Maybe two. Strain off the solution and discard the tacks. Paint the veg leather with the solution. In a few minutes, the leather will turn black! Not mildew!

This is one way black leather dye was made years and years ago. Sometimes other vegetable extracts...like logwood...were added to deepen or enrich the colour.

A more advanced experiment: Make a pair of shoes using naturally coloured veg crust. Dye one shoe black with aniline dye. Dye the other with iron black dye. Wear for one year. Condition the same and as often as you wish. After the year is up, examine the two shoes side by side. The chances are good that the shoe dyed with iron black will be cracked and the leather feeling stiff and maybe even brittle. That's why iron black or iron black based dyes lost favour.

Leather heel blocks will absorb water as the wax that seals the edges of the lifts sloughs, or is worn, off. That's why the heel is waxed in the first place. Outsole edges as well...for the same reason. Nails driven into a heel block are only impervious to moisture accretion if all water is avoided entirely (petal strewn carpets) or they are waxed daily.

Finally, I don't know how you can have it both ways--either all purpose (and even rubber cement) will block moisture migration...in which case it is occlusive and every material from cork to Topy, to full on rubber outsoles, etc., that is rubber based or mounted with rubber or neoprene cement is occlusive, or it is not. And if it is not, it will not prevent oxidation or protect the heads of those nails.

Or...you haven't thought it through and don't really and truly know what you're talking about.

--

Maybe I got this wrong......From what you are implying, water/moisture purges through the lateral portion of the base rusting nails that are coated? If so, why wouldn't the layers of the stack swell, soften and de-laminate?

- Joined

- Jan 8, 2008

- Messages

- 10,132

- Reaction score

- 5,714

Even in Traditional work, a paste or glue is used to position and mount the individual lifts. In more contemporary times neoprene cement is used. Pressure from the weight of the body keeps the lifts from delaminating until the paste can re-dry. And nails (or pegs) augment that pressure. Additionally, of course, AP is waterproof, so the bond, once established is not going to let go.

That said, lifts do swell up and sometimes do delaminate at least a little regardless of nails or cement or weight. That's the nature of water--it will always move to drier areas if given a chance. And leather is hydrophyllic. the end result is as if the water is under pressure. I don't know the scientific terminology but it's what makes it possible for the leather to "breathe"...if given a chance. If you've ever seen a shoe or boot come in out of the rain with the lifts a little proud, that's swelling from the moisture moving inward. I've seen heels gain as much as 3-5mm in height from water absorption during the rainy and / or calving season. .

But delamination is not the issue. The issue is moisture wicking into the center of the heel. Often, on well kept shoes, it is minimal. But sometimes it is...simply because of the "pressure"...more than we think or know. And it lingers long after the surface of the heel re-dries.

Then too, it depends on the leather. High quality, dense...even rolled or hammer-jacked...lifts will be far more moisture resistant than the offal that is incorporated into pre-stacked heel blocks.

Finally, what do you think that coating is? I'm not altogether sure but when I first ran across it, I immediately thought of cosmolene. Today it is probably a thin polymer. But when you drive a nail into a leather heel base, the fibers are abrasive enough in the first lift penetrated, to strip most of that coating.

Beyond all that, I suggested way back at the beginning of this particular discussion, that threaded nails, which didn't penetrate the insole and clinch on a metal plate, might be the best use of iron nails...if nails absolutely had to be used.

In passing, it's worth repeating, however--it's not mildew.

--

Maybe I got this wrong......From what you are implying, water/moisture purges through the lateral portion of the base rusting nails that are coated? If so, why wouldn't the layers of the stack swell, soften and de-laminate?

Even in Traditional work, a paste or glue is used to position and mount the individual lifts. In more contemporary times neoprene cement is used. Pressure from the weight of the body keeps the lifts from delaminating until the paste can re-dry. And nails (or pegs) augment that pressure. Additionally, of course, AP is waterproof, so the bond, once established is not going to let go.

That said, lifts do swell up and sometimes do delaminate at least a little regardless of nails or cement or weight. That's the nature of water--it will always move to drier areas if given a chance. And leather is hydrophyllic. the end result is as if the water is under pressure. I don't know the scientific terminology but it's what makes it possible for the leather to "breathe"...if given a chance. If you've ever seen a shoe or boot come in out of the rain with the lifts a little proud, that's swelling from the moisture moving inward. I've seen heels gain as much as 3-5mm in height from water absorption during the rainy and / or calving season. .

But delamination is not the issue. The issue is moisture wicking into the center of the heel. Often, on well kept shoes, it is minimal. But sometimes it is...simply because of the "pressure"...more than we think or know. And it lingers long after the surface of the heel re-dries.

Then too, it depends on the leather. High quality, dense...even rolled or hammer-jacked...lifts will be far more moisture resistant than the offal that is incorporated into pre-stacked heel blocks.

Finally, what do you think that coating is? I'm not altogether sure but when I first ran across it, I immediately thought of cosmolene. Today it is probably a thin polymer. But when you drive a nail into a leather heel base, the fibers are abrasive enough in the first lift penetrated, to strip most of that coating.

Beyond all that, I suggested way back at the beginning of this particular discussion, that threaded nails, which didn't penetrate the insole and clinch on a metal plate, might be the best use of iron nails...if nails absolutely had to be used.

In passing, it's worth repeating, however--it's not mildew.

--

Last edited:

chogall

Distinguished Member

- Joined

- Aug 12, 2011

- Messages

- 6,562

- Reaction score

- 1,166

It is helpful that you can confirm few problems with nails, as many makers apparently use them. However, this doesn't really address whether they function better or worse than pegs. How often do pegged shoes come through your shop? Have you seen any issue with pegs?

Again, pegs vs. nails may not be a huge issue, but I feel the rarefied territory of $5,000 shoes deserves attention to subtle (potential) improvements in even the smallest detail...

Of course, attention to subtle potential improvements in even the smallest detail makes horrible business sense. It makes a lot more business sense to do a 98% job and claim you're doing a 99.99% job than to actually do a 99.99% job because almost no clients would ever be the wiser. However, my interest is not in learning about how bespoke shoemakers can maximize profits, it is in learning how bespoke makers do the very best possible work.

Though distinctions exist between art and even the highest level of crafts, I still want to point out that the world is a better place because Shakespeare, Tolstoy, Rembrandt, Beethoven, etc. didn't settle for 98%. The magic comes when men strive for that final couple of percentage points. Rembrandt earned money painting portraits, but he certainly didn't settle for doing about as well as the other painters around in his day.

Yet, we are in an era where people celebrate making money to an extent never seen before, and discount the value of art and craft. People like to pay art and craft lip service and then agree amongst themselves that some guy throwing his feces against a wall has produced art in the same league as a Rembrandt or a Van Gogh. If people can agree that a wall covered with feces is great art, they can certainly tell themselves that RTW Goodyear-welted shoes by a "top designer" are the best possible shoes.

If any of you needed brain surgery, would you see the guy who was optimizing his practice for greatest profit with the fewest hours per week or the guy who sacrifices nearly all of his waking life to being the best, even though that clearly pays less?

Sure the stakes might be a lot lower with bespoke footwear, but arguing that point certainly discourages people like me from ponying up thousands of dollar for it.

Scenario 1:

"Do you peg or nail your heel seat/rand/split lift and heels?"

"No."

"kthxbye."

Scenario 2:

"Can you peg heel seat/rand/split lift and heels for my order?"

"Do you go into other peoples bedroom and tell them how to make love to their other half?"

chogall

Distinguished Member

- Joined

- Aug 12, 2011

- Messages

- 6,562

- Reaction score

- 1,166

I'm sorry...case in point--you don't know what you're talking about.

It is not mildew. It is a reaction (the initial reaction in a cycle of oxidation) between the tannin and acids in the leather and the iron.

Here is an experiment that even a non-shoemaker can do:

Take a piece of your vaunted Rendenbach. Dip it in water and let it soak for about ten minutes. Lay it on a well aerated counter flesh side up. Now place an piece of iron on it--a hammer, a pliers or even an iron nail. Let the leather dry overnight. There will be a black stain on the leather in the shape of the iron object.

Not, not, not mildew.

Here's another experiment you home experts can do: All you need is a piece of naturally coloured vegetable tanned leather, a bunch of steel wool (or a quart of old bent discarded iron tacks) and some vinegar.

Place the tacks or steel wool in a plastic bucket and cover with vinegar. Let sit overnight. Maybe two. Strain off the solution and discard the tacks. Paint the veg leather with the solution. In a few minutes, the leather will turn black! Not mildew!

This is one way black leather dye was made years and years ago. Sometimes other vegetable extracts...like logwood...were added to deepen or enrich the colour.

A more advanced experiment: Make a pair of shoes using naturally coloured veg crust. Dye one shoe black with aniline dye. Dye the other with iron black dye. Wear for one year. Condition the same and as often as you wish. After the year is up, examine the two shoes side by side. The chances are good that the shoe dyed with iron black will be cracked and the leather feeling stiff and maybe even brittle. That's why iron black or iron black based dyes lost favour.

Leather heel blocks will absorb water as the wax that seals the edges of the lifts sloughs, or is worn, off. That's why the heel is waxed in the first place. Outsole edges as well...for the same reason. Nails driven into a heel block are only impervious to moisture accretion if all water is avoided entirely (petal strewn carpets) or they are waxed daily.

Finally, I don't know how you can have it both ways--either all purpose (and even rubber cement) will block moisture migration...in which case it is occlusive and every material from cork to Topy, to full on rubber outsoles, etc., that is rubber based or mounted with rubber or neoprene cement is occlusive, or it is not. And if it is not, it will not prevent oxidation or protect the heads of those nails.

Or...you haven't thought it through and don't really and truly know what you're talking about.

--

John Lobb St James used nails to secure orthopedic/cork inserts/insoles. There were discoloration around the protruding nails. But the shoes/shoe insoles (not the insert) are far from falling apart or being damaged.

Steel shanks discolor leathers around it as well.

Discoloration doesn't equate incremental damage to what's originally been done.

I really doubt any decent bespoke maker would respond in these ways. At the very least, I imagine he would politely inquire as to the reason for the request and then decline it if they felt they couldn't accommodate it or didn't wish to accommodate it. That said, I am not a bespoke maker, so I really can't be at all sure how one would respond to such a request. I also don't understand why you would propose how a maker would respond when you aren't one and there are at least four following the thread.

Chogall, may I ask how many pairs of bespoke shoes your have purchased, not counting ones you purchased that were originally bespoken for somebody else? At the least, it would help me to judge how much you know from the client's side regarding bespoke footwear.

If you have purchased bespoke shoes for yourself, why not share some photos of them here for all of us to enjoy and/or critique? In addition, I doubt many bespoke makers would mind their clients naming them. Could you name the bespoke makers from whom you have ordered shoes?

I am neither a bespoke shoemaker nor have I ever purchased bespoke shoes, so I represent myself to know basically nothing about the topic, but am glad to ask questions and try to learn a little something here from people like DW who are so generous with their knowledge and time.

Scenario 1:

"Do you peg or nail your heel seat/rand/split lift and heels?"

"No."

"kthxbye."

Scenario 2:

"Can you peg heel seat/rand/split lift and heels for my order?"

"Do you go into other peoples bedroom and tell them how to make love to their other half?"

I really doubt any decent bespoke maker would respond in these ways. At the very least, I imagine he would politely inquire as to the reason for the request and then decline it if they felt they couldn't accommodate it or didn't wish to accommodate it. That said, I am not a bespoke maker, so I really can't be at all sure how one would respond to such a request. I also don't understand why you would propose how a maker would respond when you aren't one and there are at least four following the thread.

Chogall, may I ask how many pairs of bespoke shoes your have purchased, not counting ones you purchased that were originally bespoken for somebody else? At the least, it would help me to judge how much you know from the client's side regarding bespoke footwear.

If you have purchased bespoke shoes for yourself, why not share some photos of them here for all of us to enjoy and/or critique? In addition, I doubt many bespoke makers would mind their clients naming them. Could you name the bespoke makers from whom you have ordered shoes?

I am neither a bespoke shoemaker nor have I ever purchased bespoke shoes, so I represent myself to know basically nothing about the topic, but am glad to ask questions and try to learn a little something here from people like DW who are so generous with their knowledge and time.

chogall

Distinguished Member

- Joined

- Aug 12, 2011

- Messages

- 6,562

- Reaction score

- 1,166

I really doubt any decent bespoke maker would respond in these ways. At the very least, I imagine he would politely inquire as to the reason for the request and then decline it if they felt they couldn't accommodate it or didn't wish to accommodate it. That said, I am not a bespoke maker, so I really can't be at all sure how one would respond to such a request. I also don't understand why you would propose how a maker would respond when you aren't one and there are at least four following the thread.

Chogall, may I ask how many pairs of bespoke shoes your have purchased, not counting ones you purchased that were originally bespoken for somebody else? At the least, it would help me to judge how much you know from the client's side regarding bespoke footwear.

If you have purchased bespoke shoes for yourself, why not share some photos of them here for all of us to enjoy and/or critique? In addition, I doubt many bespoke makers would mind their clients naming them. Could you name the bespoke makers from whom you have ordered shoes?

I am neither a bespoke shoemaker nor have I ever purchased bespoke shoes, so I represent myself to know basically nothing about the topic, but am glad to ask questions and try to learn a little something here from people like DW who are so generous with their knowledge and time.

Do you intend to quiz your future shoemakers on how many pairs have they make themselves, not counting ones they made under other workshops for other shoemakers? It might help you judging how much they know about making bespoke shoes!

j-mac

Member

- Joined

- Feb 28, 2016

- Messages

- 18

- Reaction score

- 28

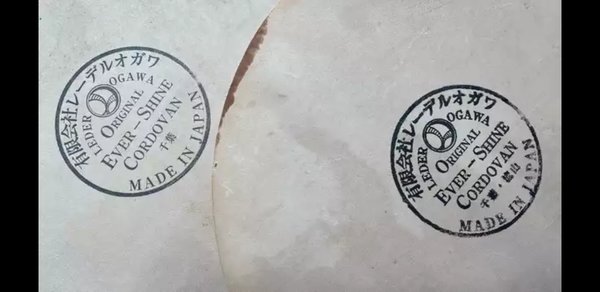

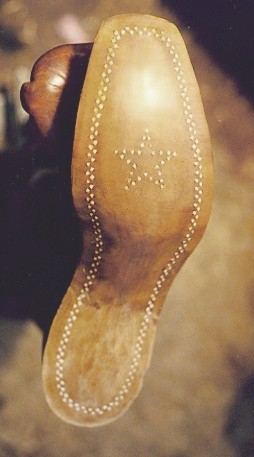

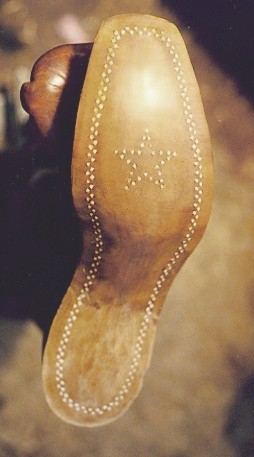

Interestingly enough both pix came from D Wegan Instagram. Not sure if he did it as a discovery practice or for actual customer delivery. Or it's from some out workers.

I've also seen a Spanish maker doing both.

Thus my curiosity.

This is how I do it, I saw it done 2 or 3 different ways during my apprenticeship and chose this method as I like the way it pulls the leather in around the seat.

- Joined

- Jan 8, 2008

- Messages

- 10,132

- Reaction score

- 5,714

I don't doubt that...I don't doubt or question your first hand experiences. But it has never, to my knowledge, happened to a pair of heels that I built. Never.

Why do you think that is?

Step back a moment and think about this....people are so different. The stresses that they put their shoes through, and the way they wear them, are so different. How can you and so many others so blithely say "such and such is not a problem" or suggest that since you've never seen it, it can't happen? It's a foolish position to take, IMO, esp. if you don't have the first hand experience.

But again, why do you think my heels don't come off?

I'll tell you why I think they don't come off--it's because pegging is not like driving a nail. Not really. And too many makers think it is.

You have to drive more pegs than you would nails. And they have to support each other. And they have to be driven into leather that is at just the right level of temper/moisture--if the leather is too wet initially, you get loose pegs, too dry, loose pegs.

The pegs I use for stacking heels are almost one inch long. That means that each peg in each layer, penetrates three to four+ layers below it...depending on the thickness of each lift.

When I peg a waist or a full sole, I use two rows rather than one--one row is not adequate to hold the outsole in place reliably, despite what any maker (primarily Austro-Hungarian makers, AFAIK) thinks. That's not been my experience...and evidently not been the experience of all too many consumers who post here, complaining. The main connection on such work, IMO, is the all-purpose cement--the pegs are just for show.

And I peg at 10 per inch, interlocked.

I'll tell you why my heels have never come off...it's not because I'm some crazy talented maker, or never make mistakes, or know it all, or even more than my peers. Nor is it because I make shoes that no one wears anywhere but on carpets.

It's because I obsess about details like rust and wax and temper and how many pegs per inch. And even the alignment of the peg in the hole.

Heaven is in the details.

--

I never said that your heel bases would come off.

I answered the question asked of me. And, yes I've seen them sheered off. Just sharing my experience.

I don't doubt that...I don't doubt or question your first hand experiences. But it has never, to my knowledge, happened to a pair of heels that I built. Never.

Why do you think that is?

Step back a moment and think about this....people are so different. The stresses that they put their shoes through, and the way they wear them, are so different. How can you and so many others so blithely say "such and such is not a problem" or suggest that since you've never seen it, it can't happen? It's a foolish position to take, IMO, esp. if you don't have the first hand experience.

But again, why do you think my heels don't come off?

I'll tell you why I think they don't come off--it's because pegging is not like driving a nail. Not really. And too many makers think it is.

You have to drive more pegs than you would nails. And they have to support each other. And they have to be driven into leather that is at just the right level of temper/moisture--if the leather is too wet initially, you get loose pegs, too dry, loose pegs.

The pegs I use for stacking heels are almost one inch long. That means that each peg in each layer, penetrates three to four+ layers below it...depending on the thickness of each lift.

When I peg a waist or a full sole, I use two rows rather than one--one row is not adequate to hold the outsole in place reliably, despite what any maker (primarily Austro-Hungarian makers, AFAIK) thinks. That's not been my experience...and evidently not been the experience of all too many consumers who post here, complaining. The main connection on such work, IMO, is the all-purpose cement--the pegs are just for show.

And I peg at 10 per inch, interlocked.

I'll tell you why my heels have never come off...it's not because I'm some crazy talented maker, or never make mistakes, or know it all, or even more than my peers. Nor is it because I make shoes that no one wears anywhere but on carpets.

It's because I obsess about details like rust and wax and temper and how many pegs per inch. And even the alignment of the peg in the hole.

Heaven is in the details.

--

Last edited:

I think it is completely fair to ask a man how experienced he is at his trade if you are going to pay him for work. Experience counts for an awful lot.

Your lack of an answer regarding how many bespoke shoes you have bespoken is rather telling. Having no experience is not a good reason to dismiss its importance. There is no shame in having no experience, as long as one is open about it, expresses a desire to learn, and doesn't presume to teach people that which one doesn't know.

Chogall, you care a lot about footwear and you know a certain kind of information about it that you have gleaned indirectly from others, but you are just playing whisper down the lane, which is fairly inexcusable when we are so fortunate to have multiple true experts here to share their first-hand knowledge with us.

Chogall, couldn't you spend the time you currently spend here actually learning for yourself how to make shoes? I bet you would enjoy it more and learn a lot more. Alternatively, if there is some area of human endeavor with which you have first-hand experience, wouldn't you enjoy sharing your first-hand knowledge of it in the appropriate forum?

Chogall, I really do wish you the best. I am not saying you're a bad person. This is not personal in any way. I am only commenting on your participation here on this thread, which I hope is only a very small part of your life and, hence, not really representative of you.

Do you intend to quiz your future shoemakers on how many pairs have they make themselves, not counting ones they made under other workshops for other shoemakers? It might help you judging how much they know about making bespoke shoes!

I think it is completely fair to ask a man how experienced he is at his trade if you are going to pay him for work. Experience counts for an awful lot.

Your lack of an answer regarding how many bespoke shoes you have bespoken is rather telling. Having no experience is not a good reason to dismiss its importance. There is no shame in having no experience, as long as one is open about it, expresses a desire to learn, and doesn't presume to teach people that which one doesn't know.

Chogall, you care a lot about footwear and you know a certain kind of information about it that you have gleaned indirectly from others, but you are just playing whisper down the lane, which is fairly inexcusable when we are so fortunate to have multiple true experts here to share their first-hand knowledge with us.

Chogall, couldn't you spend the time you currently spend here actually learning for yourself how to make shoes? I bet you would enjoy it more and learn a lot more. Alternatively, if there is some area of human endeavor with which you have first-hand experience, wouldn't you enjoy sharing your first-hand knowledge of it in the appropriate forum?

Chogall, I really do wish you the best. I am not saying you're a bad person. This is not personal in any way. I am only commenting on your participation here on this thread, which I hope is only a very small part of your life and, hence, not really representative of you.

Your humility and the photos of your work speak volumes. Though much of what you say is specific to shoemaking, so much of it is true of in all "professions," using the term in its broadest sense.

However, your approach to you work, as you well know, puts you at odd with the ethos of this age, which is "fast, easy money."

I'll tell you why my heels have never come off...it's not because I'm some crazy talented maker or because I make shoes that no one wears anywhere but on carpets. It's because I obsess about details like rust and wax and temper and how many pegs per inch.

Heaven is is the details.

Your humility and the photos of your work speak volumes. Though much of what you say is specific to shoemaking, so much of it is true of in all "professions," using the term in its broadest sense.

However, your approach to you work, as you well know, puts you at odd with the ethos of this age, which is "fast, easy money."

- Joined

- Jan 8, 2008

- Messages

- 10,132

- Reaction score

- 5,714

And it is completely fair to ask a maker to use pegs rather than nails,

This is what "bespoke" is all about. In fact it is nearly the definition of bespoke.

It's always fair to ask. It's always fair to request.

Just don't expect a maker to always say yes.

Then it's in your hand...your decision.

I think it is completely fair to ask a man how experienced he is at his trade if you are going to pay him for work. Experience counts for an awful lot.

And it is completely fair to ask a maker to use pegs rather than nails,

This is what "bespoke" is all about. In fact it is nearly the definition of bespoke.

It's always fair to ask. It's always fair to request.

Just don't expect a maker to always say yes.

Then it's in your hand...your decision.

Classic Menswear Featured products

-

Carmina - Norwegian Derby Shoes Introducing the classy six eyelet split toe derby in a burgundy Shell Cordovan from Horween Chicago. This style features a single oak-bark tanned sole from Rendembach Jr. and full calf lining color brown.

-

LuxeSwap Auction - Vintage Antique United States Naval Navy Denim Deck Jacket A piece for denim heads, vintage collectors, streetwear enthusiasts and menswear enthusiasts alike, this extremely rare early US Naval issued deck jacket in raw denim is not likely to ever show up at auction again anytime soon. A Haleys Comet of menswear items, offered at auction at a $9.99 starting bid with no reserve.

LuxeSwap Auction - Vintage Antique United States Naval Navy Denim Deck Jacket A piece for denim heads, vintage collectors, streetwear enthusiasts and menswear enthusiasts alike, this extremely rare early US Naval issued deck jacket in raw denim is not likely to ever show up at auction again anytime soon. A Haleys Comet of menswear items, offered at auction at a $9.99 starting bid with no reserve. -

Kirby Allison - Luxury Suit Hanger - $32 Kirby Allison's Luxury Wooden Suit Hangers protect your suits from stretched collars and droopy shoulders. Our wooden suit hangers provide five-times more support than average hangers and will protect and extend the life of your most important garments.

Kirby Allison - Luxury Suit Hanger - $32 Kirby Allison's Luxury Wooden Suit Hangers protect your suits from stretched collars and droopy shoulders. Our wooden suit hangers provide five-times more support than average hangers and will protect and extend the life of your most important garments.

FEATURED PRODUCTS

-

LuxeSwap Auction - Vintage Antique United States Naval Navy Denim Deck Jacket

A piece for denim heads, vintage collectors, streetwear enthusiasts and menswear enthusiasts alike, this extremely rare early US Naval issued deck jacket in raw denim is not likely to ever show up at auction again anytime soon. A Haleys Comet of menswear items, offered at auction at a $9.99 starting bid with no reserve.

LuxeSwap Auction - Vintage Antique United States Naval Navy Denim Deck Jacket

A piece for denim heads, vintage collectors, streetwear enthusiasts and menswear enthusiasts alike, this extremely rare early US Naval issued deck jacket in raw denim is not likely to ever show up at auction again anytime soon. A Haleys Comet of menswear items, offered at auction at a $9.99 starting bid with no reserve.

-

Wellington Chore Boot - Special Introductory Price! $495

Introducing the latest addition to Nicks Handmade Boots collection: The Wellington Chore Boot. Engineered for the rigors of daily tasks, this boot is more than just footwear; it's a reliable companion for your everyday adventures. Crafted with convenience in mind, its effortless pull-on design ensures you're always ready to tackle whatever the day throws your way.

Wellington Chore Boot - Special Introductory Price! $495

Introducing the latest addition to Nicks Handmade Boots collection: The Wellington Chore Boot. Engineered for the rigors of daily tasks, this boot is more than just footwear; it's a reliable companion for your everyday adventures. Crafted with convenience in mind, its effortless pull-on design ensures you're always ready to tackle whatever the day throws your way.

-

Besnard - Made to Order Trousers - $351 Design your ideal pair of trousers by selecting a fabric, deciding between single or double pleats, choosing a zip or button fly, and opting for side adjusters or belt loops.

Latest posts

- Replies

- 43,971

- Views

- 7,903,820

- Replies

- 81,641

- Views

- 14,018,080

- Replies

- 8,827

- Views

- 2,404,523

- Replies

- 5,475

- Views

- 1,266,887

- Replies

- 36,606

- Views

- 4,452,973

Similar threads

- Replies

- 43

- Views

- 31,217

- Replies

- 17

- Views

- 14,521

- Replies

- 130

- Views

- 126,622

- Replies

- 1,320

- Views

- 202,354

- Replies

- 6

- Views

- 6,079

Featured Sponsor

Forum Sponsors

- American Trench

- AMIDÉ HADELIN

- Archibald London

- The Armoury

- Arterton

- Besnard

- Canoe Club

- Capra Leather

- Carmina

- Cavour

- Crush Store

- De Bonne Facture

- Drinkwater's Cambridge

- Drop93

- eHABERDASHER

- Enzo Custom

- Epaulet

- Exquisite Trimmings

- Fils Unique

- Gentlemen's Footwear

- Giin

- Grant Stone

- House of Huntington

- IsuiT

- John Elliott

- Jonathan Abel

- Kent Wang

- Kirby Allison

- Larimars Clothing

- Lazy Sun

- LuxeSwap

- Luxire Custom Clothing

- Nicks Boots

- No Man Walks Alone

- Once a Day

- Passus shoes

- Proper Cloth

- SARTORIALE

- SEH Kelly

- Self Edge

- Shop the Finest

- Skoaktiebolaget

- Spier and MacKay

- Standard and Strange

- Bespoke Shoemaker Szuba

- Taylor Stitch

- TLB Mallorca

- UNI/FORM LA

- Vanda Fine Clothing

- Von Amper

- Wrong Weather

- Yeossal

- Zam Barrett

Staff online

-

JenAdministrator

Members online

- arid

- ghdvfddzgzdzg

- rob g

- ScottyK

- johnyy123

- Bon Vivant Life

- dynemacron

- velomane

- WhyUEarly

- salzcamino

- CLH03

- Redtop

- kwonster

- serbarristan

- lagsun

- kjb

- rapide66

- Jen

- Kangnamstyles

- TomCollinz

- Hombre Secreto

- William Kazak

- kevinftwman

- davidc

- FLtheatretech

- greekgeek

- clt3

- NicaSuave

- Beav

- oudwood

- howardeb

- jeremygo

- Limboroom

- stubbsj20

- Mr SHIFTY

- Oligarch

- mak1277

- thepatinaarena

- nsubrmnn

- qtip.416

- Retri

- WaltDud

- ddohnggo

- Sheepdog

- tertbutyl

- ElliotG

- Pakman161

- slacquer

- trancebepopulate

- WhereNext

Total: 3,659 (members: 105, guests: 3,554)