shoefan

Senior Member

- Joined

- Jul 27, 2003

- Messages

- 853

- Reaction score

- 203

STYLE. COMMUNITY. GREAT CLOTHING.

Bored of counting likes on social networks? At Styleforum, you’ll find rousing discussions that go beyond strings of emojis.

Click Here to join Styleforum's thousands of style enthusiasts today!

Styleforum is supported in part by commission earning affiliate links sitewide. Please support us by using them. You may learn more here.

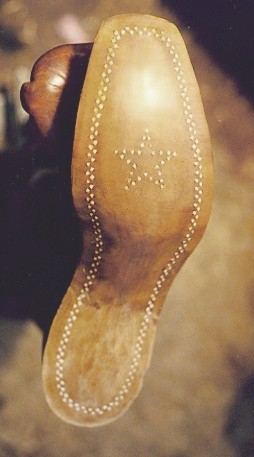

Let me ask you a question...no, I'm not trying to put you on the spot or challenge your choices. Your inseam job from heel to toe is unimpeachable. I ask with all sincere and due respect... But do you think that the leather around the seat in this photo (below) is not "pulled in around the seat"? Or inadequately pulled in around the seat?

Let me ask you a question...no, I'm not trying to put you on the spot or challenge your choices. Your inseam job from heel to toe is unimpeachable. I ask with all sincere and due respect...

But do you think that the leather around the seat in this photo (below) is not "pulled in around the seat"? Or inadequately pulled in around the seat?

I don't doubt that...I don't doubt or question your first hand experiences. But it has never, to my knowledge, happened to a pair of heels that I built. Never.

Why do you think that is?

Step back a moment and think about this....people are so different. The stresses that they put their shoes through, and the way they wear them, are so different. How can you and so many others so blithely say "such and such is not a problem" or suggest that since you've never seen it, it can't happen? It's a foolish position to take, IMO, esp. if you don't have the first hand experience.

But again, why do you think my heels don't come off?

I'll tell you why I think they don't come off--it's because pegging is not like driving a nail. Not really. And too many makers think it is.

You have to drive more pegs than you would nails. And they have to support each other. And they have to be driven into leather that is at just the right level of temper/moisture--if the leather is too wet initially, you get loose pegs, too dry, loose pegs.

The pegs I use for stacking heels are almost one inch long. That means that each peg in each layer, penetrates three to four+ layers below it...depending on the thickness of each lift.

When I peg a waist or a full sole, I use two rows rather than one--one row is not adequate to hold the outsole in place reliably, despite what any maker (primarily Austro-Hungarian makers, AFAIK) thinks. That's not been my experience...and evidently not been the experience of all too many consumers who post here, complaining. The main connection on such work, IMO, is the all-purpose cement--the pegs are just for show.

And I peg at 10 per inch, interlocked.

I'll tell you why my heels have never come off...it's not because I'm some crazy talented maker, or never make mistakes, or know it all, or even more than my peers. Nor is it because I make shoes that no one wears anywhere but on carpets.

It's because I obsess about details like rust and wax and temper and how many pegs per inch. And even the alignment of the peg in the hole.

Heaven is in the details.

--

Fair 'nuff.....We can use the same logic here. The same reason I never get shoes that we installed flush mounted metal toe plates returned where something failed.

I've stressed this before and it bears repeating....."if done correctly".

Conversely, why not inseam the welt the same way as you do heel seat stitching if you think its as strong? Just curious.

I accept that. But too many conversations with you, specifically, as well as others here, leave me wondering what kind of definition you have for 'failed."

If you were taking a shoe apart that had a flush mounted toe plate and happened to see...were mindful enough to look for...holes in the inseam, but the welt seemed intact and you had no doubts that you could stitch on another outsole, would you consider that there was a problem? Would you see "failed" or just "whatever, not a problem"?

If you pull apart a shoe and see that the cork has been fugitive in the forepart, would you ask yourself "why should that be?" Or "how can the cork do its job if it doesn't stay in one place?"

If you see gemming coming loose in a one inch section, does it occur to you that it has failed? It's not just wear and tear. If it is not functioning or in exactly the same state as it was intended to be when implemented, how can it be anything other than failed?

Or do you dismiss all these things as inconsequential, simply because they don't immediately affect whether you can do the job, today?

Definitions determine standards. Dumbing them down is just evasion.

I think it is completely fair to ask a man how experienced he is at his trade if you are going to pay him for work. Experience counts for an awful lot.

Your lack of an answer regarding how many bespoke shoes you have bespoken is rather telling. Having no experience is not a good reason to dismiss its importance. There is no shame in having no experience, as long as one is open about it, expresses a desire to learn, and doesn't presume to teach people that which one doesn't know.

Chogall, you care a lot about footwear and you know a certain kind of information about it that you have gleaned indirectly from others, but you are just playing whisper down the lane, which is fairly inexcusable when we are so fortunate to have multiple true experts here to share their first-hand knowledge with us.

Chogall, couldn't you spend the time you currently spend here actually learning for yourself how to make shoes? I bet you would enjoy it more and learn a lot more. Alternatively, if there is some area of human endeavor with which you have first-hand experience, wouldn't you enjoy sharing your first-hand knowledge of it in the appropriate forum?

Chogall, I really do wish you the best. I am not saying you're a bad person. This is not personal in any way. I am only commenting on your participation here on this thread, which I hope is only a very small part of your life and, hence, not really representative of you.

I didn't say anything about "strong" as it relates to the heel seat stitching.

I outlined some of my reasons for preferring this approach in an earlier post in this thread. Parenthetically, I also remarked that I admired the "British" technique and had it on my bucket list to try...with modifications.

And just for the record...you can often satisfy your curiosity simply by reading for content and/or following a thread from its beginning, if curiosity is really the issue.

I accept that. But too many conversations with you, specifically, as well as others here, leave me wondering what kind of definition you have for 'failed."

If you were taking a shoe apart that had a flush mounted toe plate and happened to see...were mindful enough to look for...holes in the inseam, but the welt seemed intact and you had no doubts that you could stitch on another outsole, would you consider that there was a problem? Would you see "failed" or just "whatever, not a problem"?

If a pegged heel sheared off -or- loosened to me it failed. All the other stuff you mentioned could happen with -or without metal toe plates being installed. If we happen across any of those issues we simply correct the problem. In most cases we don't even tell the customer. No big deal if done correctly.

Maybe strong is not the right word, but jmac said he likes the way the "British" heel seat stitching pulls the leather around the insole and you prefer using the "French" way. My question is, why not use the "French" way of doing heel seat stitching for the whole inseaming?

Misses the point...everything is down to "if done correctly," including choosing not to do something. It's not a big deal to you because you're not a shoemaker. Can't really do anything to avoid the problems...esp. if you don't see it/define it as a problem. Plus it's your job business's to pull it together, whether it's a problem or not.

I've only seen one pair of hand sewn welted shoes w/ flushed metal toe plates being open; there's no damage to the inseam. But then you probably have seen 1000x more shoes with metal toe plates opened up than I did and @Nick V.

1000x than yours.

Maybe you didn't get the answer you were looking for....

I didn't miss the point in fact I gave you an honest answer based on my experience.

I am in know way representing anyone else but myself. However, I would venture to guess that most (if no all) the other makers that have been involved in this thread would agree that you over dramatize many issues including the ones you mentioned above.. They know as well as I these major problems that you allude to are no big deal to correct.

Last, I am not interested in being dragged into a pissing match.

This is shoe-making and repair, not rocket science or brain surgery.

Nicks Boots - Wickett & Craig English Bridle Veg Tan Leather - $759

These boots are made from 6.5 oz Wickett & Craig English Bridle Leather. This tannery has been making leather the old fashioned way since 1867. Each side can take about six weeks to produce, making it a significantly longer production time than most leather on the market.

Nicks Boots - Wickett & Craig English Bridle Veg Tan Leather - $759

These boots are made from 6.5 oz Wickett & Craig English Bridle Leather. This tannery has been making leather the old fashioned way since 1867. Each side can take about six weeks to produce, making it a significantly longer production time than most leather on the market.