- Joined

- Sep 6, 2010

- Messages

- 1,862

- Reaction score

- 990

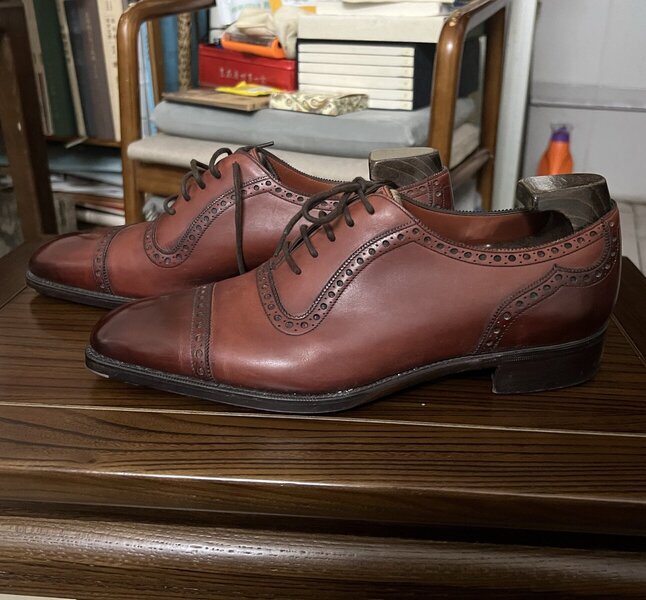

Love that Deco calf's faded/purplish accent on the toe, but should probably stick to neutral colored polish

Love that Deco calf's faded/purplish accent on the toe, but should probably stick to neutral colored polish

Last edited: