induere_to

Senior Member

- Joined

- Aug 6, 2017

- Messages

- 583

- Reaction score

- 7,485

Hey man, best of luck with your mental health issues, I hope you are getting whatever help you need. I'm glad to see you feel comfortable talking about it.

My understanding of this thread was it was a place for people to post their MTM garments and talk about the experiences they've had as customers and perhaps the iterative process to get to where they are now, so I dont want to belabor this back and forth with you too much. However, a final reply before moving on:

So, your algorithm is really just "ease". Chest measurement plus 4", waist plus 3" etc. I think thats pretty standard, and once again a benefit of try-on so you can actually see where you are starting from. On that subject, I cant understand why a try-on would cost more than your trial garments, and you can reuse them over and over. 38R-50R is only 7 suits, so I cant see how that would get remotely close to $20k. The closet space is a real concern, but rolling racks, etc.

As for the shoulder width, sleeve length and body length being the most important measures, I couldnt disagree more strongly. The most important measurements are shoulder slope and posture, because you broadly cant correct for those once a garment is made. They also dictate most of the other things about how the item fits, including the location of the armhole. Static, 2D measurements are important, but they are incomplete. Two people with the exact same measures could have wildly different shapes, posture, arm position/ sleeve pitch, pelvic tilt, etc. Some of those things you can eyeball, but thats a guess. Some of those things you wont know until theres a try-on, basted garment or finished garment on the customer. Context is incredibly important.

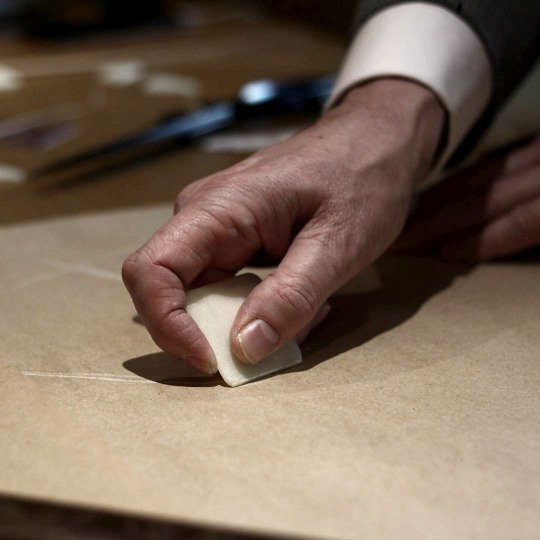

I also wanted to circle back about your patterns, because I'm fascinated. Are you actually producing the patterns that you send to the factory to be used for fabrication? Are you using software or freehand drawing them? I cant imagine how complicated and difficult that would be and how much effort must have gone into teaching yourself how to do that. Really impressive and I'd be interested in hearing about how you learned.

FInally, the grey pants look nice, good job.

I think you need to re-read what I wrote about how I determine a persons posture. I agree that the most important element to perfect a garments fit is shoulder posture and balance. But how are you going to measure that without a trial garment? So many people on this forum look at shoulder divots, thinking they're caused because the shoulder is narrow but that's not always the case. Actually, more than likely it isn't. Could be shoulders that are too wide, dropped, rolled or even the construction of what's inside the sleeve head. The closer the garment fits, the easier it is to resolve the issues.

And no, I meant algorithm, not ease. I've been selling ready to wear long enough to know that base measurements don't always highlight posture issues. Several of the companies I do freelance fittings for does it the same way as you. If a guy has erect posture, and sloped shoulders, you find yourself reducing a lot of fabric in the back of the chest. But, when focusing on it more clearly, turns out you're no longer pinning excess fabric, but instead you're actually pinning a posture correction that can easily be mistaken for something a lot less critical. Guys can have big guts with narrow shoulders or small guts with wide shoulders. Taking proper measurements and making a trial garment based off of those measurements to provide a better foundation to fit someone properly is the way that I found best to go about understanding how to accommodate for a persons posture. I asked a bespoke tailor (that I work very closely with) about his measurement algorithms for trousers so I could bounce ideas around and compare methods and was honestly rather dissatisfied by his answer. I disliked his lack of attention to something so crucial that when he made me a pair of trousers, I ended up questioning him about whether his lack of algorithm was cause for my qualm in the way the trousers fit. He actually laughed and said it was possible. After that, he asked for my help to develop better trouser patterns. Not trying to brag, but to prove that measurement algorithm, from my perspective, is extremely important. But if you're reducing finished measurements only then it really doesn't make much of a difference.

Also, if you're working off even-number sizing only, it's harder to accommodate for the guys that have odd number sizing. The way I go about it, if I measure a guy by one eighth of an inch, that's the size he gets in his trial garment. Posture is soooooooooo much easier to correct once you have a template that's closest to the persons actual measurements.

I started doing fittings this way when I had a client come in to Spier and Mackay looking for a tuxedo for his wedding. He and his brother both had severe scoliosis and they both had dwarfism. The owner of SM messaged me asking why I'd even take-on a customer with such crazy posture, to which I requested he tried doing a trial garment. To date, the results of those garments are among the best I've ever done; and I've learned so much since then. I can only think about how well I could do it now if I were to see them again. To be honest, I don't even think they realize all the work put into those garments, but I'm satisfied being the only one that knows. I posted pictures a while back from this fitting.