mw313

Distinguished Member

- Joined

- Mar 21, 2014

- Messages

- 2,452

- Reaction score

- 525

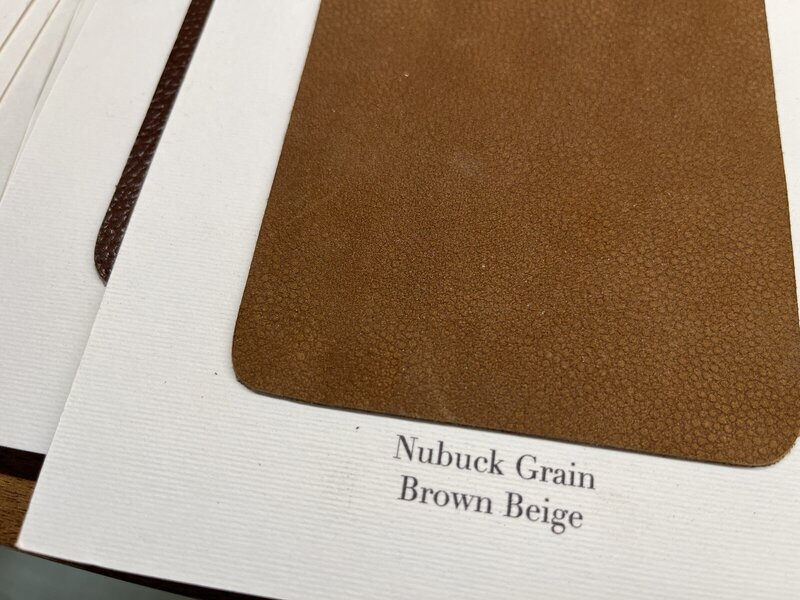

Next step was to prepare the suede and calf components to be sewn together. They were lined up and then used a sewing machine on a very fine setting. Sewing was done to attach the lining to the upper parts as well.

He also made the brogue/punching details for the upper along with the medallion by hand.

He also made the brogue/punching details for the upper along with the medallion by hand.